- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

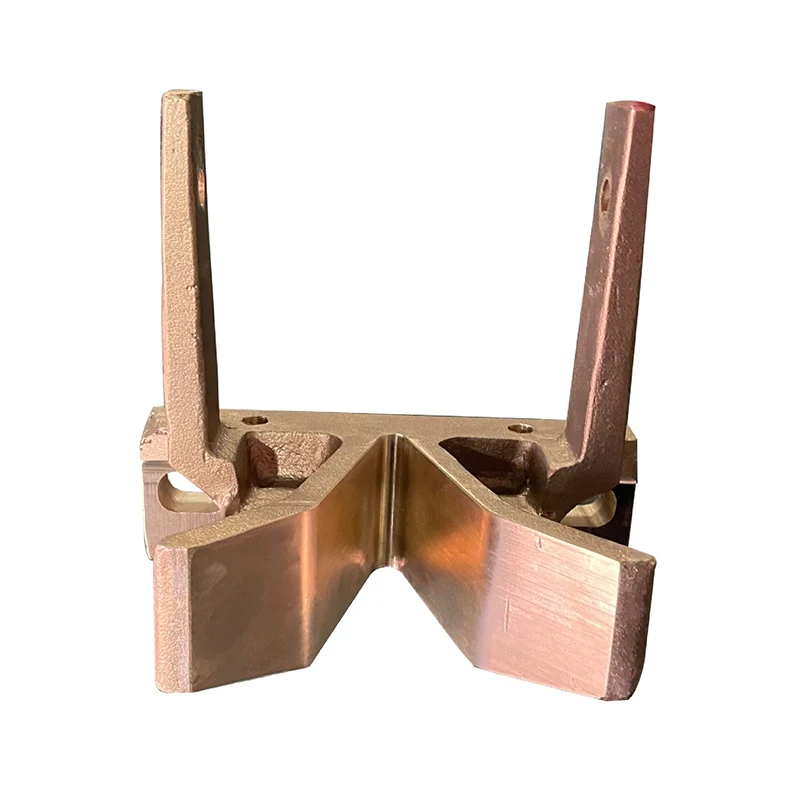

Electroplated Conductive Copper V-Base Sand Casting Copper Parts

Send Inquiry

What are the advantages of Electroplated Conductive Copper V-Base Sand Casting Copper Parts produced by Xingxin Machinery Factory?

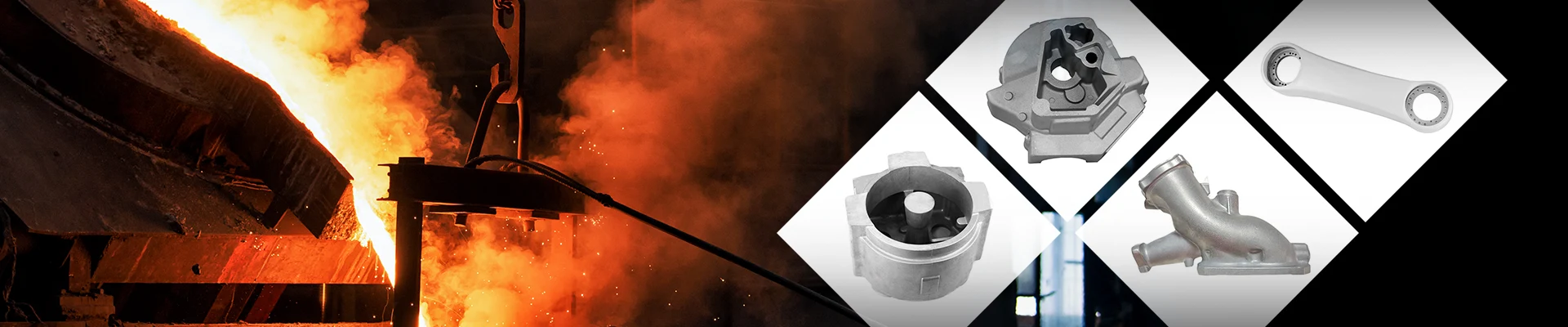

Xingxin sand casting process after years of research precipitation, product quality is mature and controllable. Sand casting copper is through the sand casting, the first to make molds, and then the melted copper alloy is poured into them, and finally subsequent processing and surface treatment, Xing Xin sand casting process can improve the Electroplated Conductive Copper V-Base Sand Casting Copper Parts molding accuracy and integrity, and can greatly reduce the subsequent processing procedures. Brass sand turning process has the characteristics of adjustable coarseness and fineness, which can meet the surface treatment requirements of different needs. The surface of the products treated by the brass sand turning process not only has the effect of frosting, but also can improve the aesthetics of the brass products, with relatively good strength and heat resistance, strong toughness, long service life, tougher and more durable, and able to withstand higher temperatures and greater deformation, which is suitable for seals of higher requirements, Mechanical parts, automobile braking system and other fields, is also suitable for the manufacture of high-precision parts. With good chemical stability and processability and corrosion resistance, it is widely used in electrical, aerospace and other fields, and has good application prospects.

Dongguan Xingxin Machinery Hardware Fittings Co., Ltd. specializes in the production of various grades of Electroplated Conductive Copper V-Base Sand Casting Copper Parts, copper alloy castings, aluminum alloy castings, zinc alloy castings, forging parts, various grades of cast iron parts and other machinery parts and furniture parts, to the production of safe and environmentally friendly, quality assurance production concept, to provide customers with customized services, to meet the customer's needs for a variety of hardware and machinery parts.