- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

Faucet 4-Way Flow Connector Forged Copper Parts

Send Inquiry

What are the advantages of Faucet 4-Way Flow Connector Forged Copper Parts produced by Xingxin Machinery Factory? Xingxin tumble forging copper process has been studied and precipitated for many years, and the product quality is mature and controllable.

The forging of copper alloy can be performed through two methods: hot forging and cold forging:

1. Hot Forging

Hot forging involves deforming copper alloy at high temperatures, taking advantage of its plasticity under heat. This method is ideal for producing large and high-precision copper alloy forgings, significantly enhancing the product's strength and toughness.

2. Cold Forging

Cold forging is carried out by hammering or applying pressure to the copper alloy at room temperature. This technique is suitable for creating small copper alloy forgings and precision components with low pressure.

Faucet 4-Way Flow Connector Forged Copper Parts offers several advantages due to its excellent plasticity and toughness, allowing it to meet various molding requirements. The good thermal conductivity of copper alloy ensures that forgings do not deform or crack during the process. Additionally, its corrosion resistance and abrasion resistance make it a preferred material in many industrial fields.

Faucet 4-Way Flow Connector Forged Copper Parts possess a range of exceptional properties, making them widely applicable in aerospace, electrical, construction, automotive, and other industries. Common applications include wires, bearings, airtight components, and more.

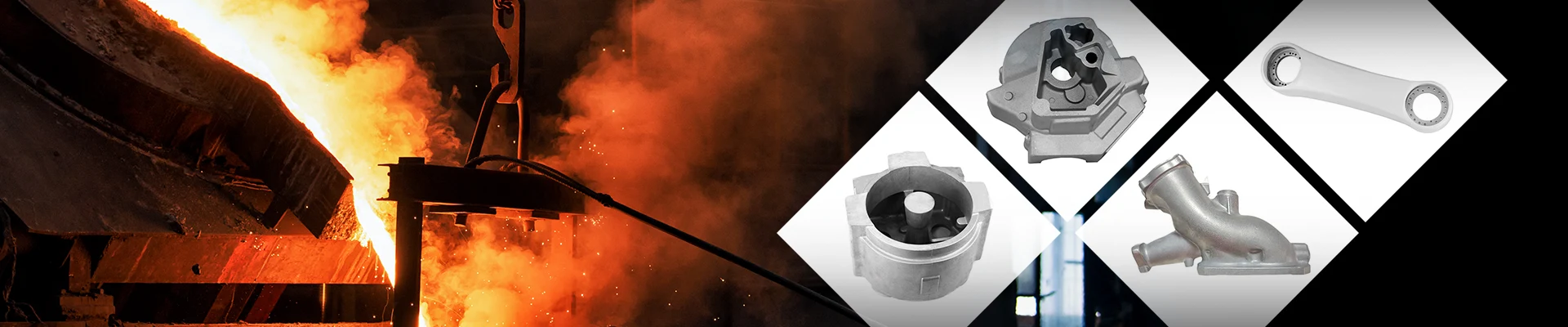

The production of various grades of copper alloy castings, aluminum alloy castings, zinc alloy castings, Faucet 4-Way Flow Connector Forged Copper Parts, forging parts, various grades of cast iron parts, and other machinery and furniture parts is the area of expertise of Dongguan Xingxin Machinery Hardware Fittings Co., Ltd. Additionally, the company specializes in the production of safe and environmentally friendly, quality assurance production concepts, offers customized services to customers, and meets their needs for a wide range of hardware and machinery parts.