- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

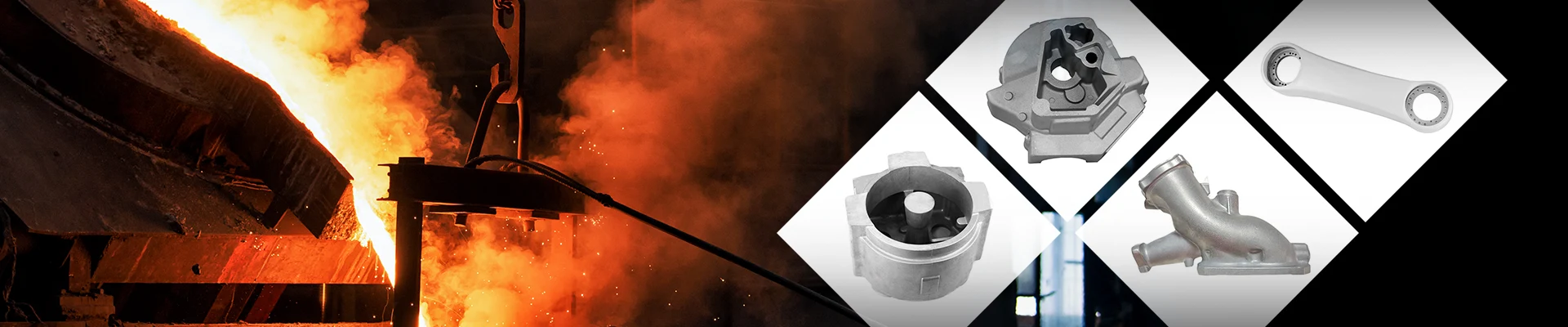

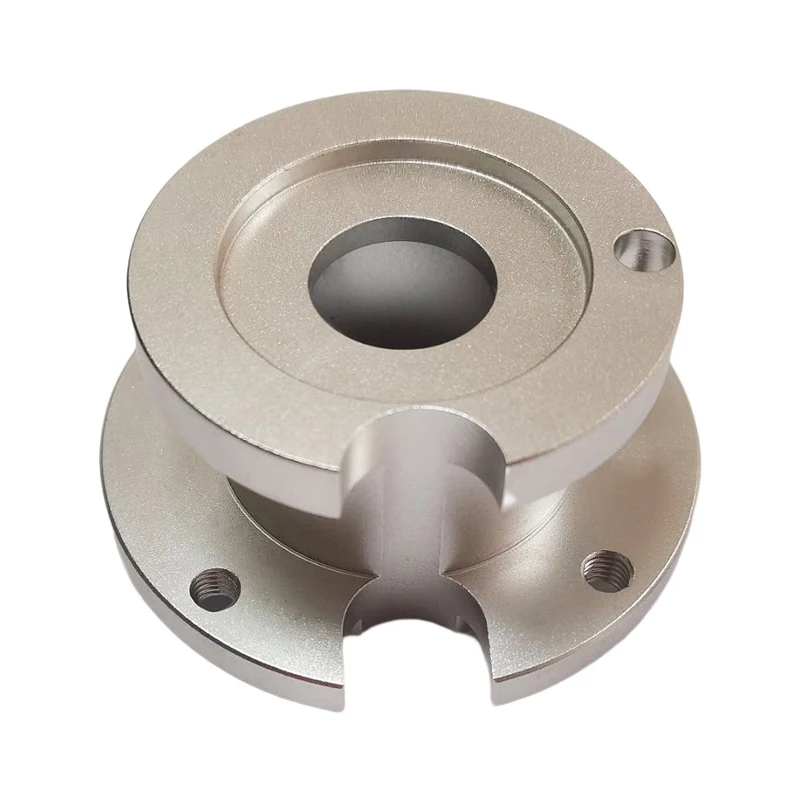

Forged Aluminum Parts for Scroll Discs

Send Inquiry

What are the advantages of Forged Aluminum Parts for Scroll Discs produced by Xingxin Machinery Factory? Xingxin sand forging aluminum process after years of time research precipitation, product quality is mature and controllable. Aluminum alloy is widely used in industrial manufacturing because of its lighter weight, good corrosion resistance and high strength.

1. Fine grain: Forging can make the grain of Forged Aluminum Parts for Scroll Discs become finer, thus improving its strength and toughness.

2. No internal defects: During the forging process of aluminum alloy, the material will go through several procedures such as heating and cooling to eliminate internal defects and improve product quality.

3. basically no change in chemical composition: the forging process does not change the chemical composition of the Forged Aluminum Parts for Scroll Discs, which ensures that the composition of the product is accurate.

4. Material saving: forging can ensure maximum utilization of materials and reduce waste by adjusting the shape and size of materials and other measures.

Aluminum alloy forging can be divided into two ways: hot forging and cold forging. Among them, hot forging is mainly applicable to the manufacture of large, complex aluminum alloy components, and cold forging is mainly applicable to the manufacture of small, precision components.

1. Hot forging: hot forging is carried out at high temperature, usually around 600-700°C. At this temperature, the aluminum alloy is relatively high. At this temperature, aluminum alloy is soft and easy to change shape. Hot forging can be divided into two ways: free forging and die forging.

2. Cold forging: the cold forging temperature of Forged Aluminum Parts for Scroll Discs is usually carried out at room temperature, cold forging can make the workpiece higher density and better mechanical properties.

Forged Aluminum Parts for Scroll Discs is widely used in automobile, ship, aerospace, electronics, equipment manufacturing and other fields due to its good physical and chemical properties. Among them, aluminum alloy forging is especially widely used in aerospace, ships and other fields.

Dongguan Xingxin Machinery Hardware Fittings Co., Ltd. specializes in the production of various grades of copper alloy castings, Forged Aluminum Parts for Scroll Discs, aluminum alloy castings, zinc alloy castings, forging parts, various grades of cast iron parts and other machinery parts and furniture parts, to the production of safe and environmentally friendly, quality assurance production concept, to provide customers with customized services, to meet the customer's needs for a variety of hardware and machinery parts.