- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

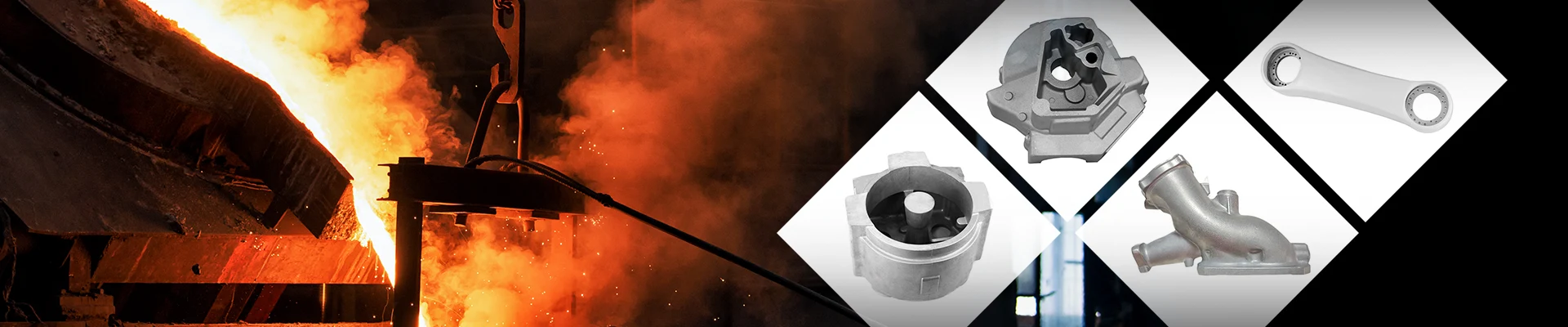

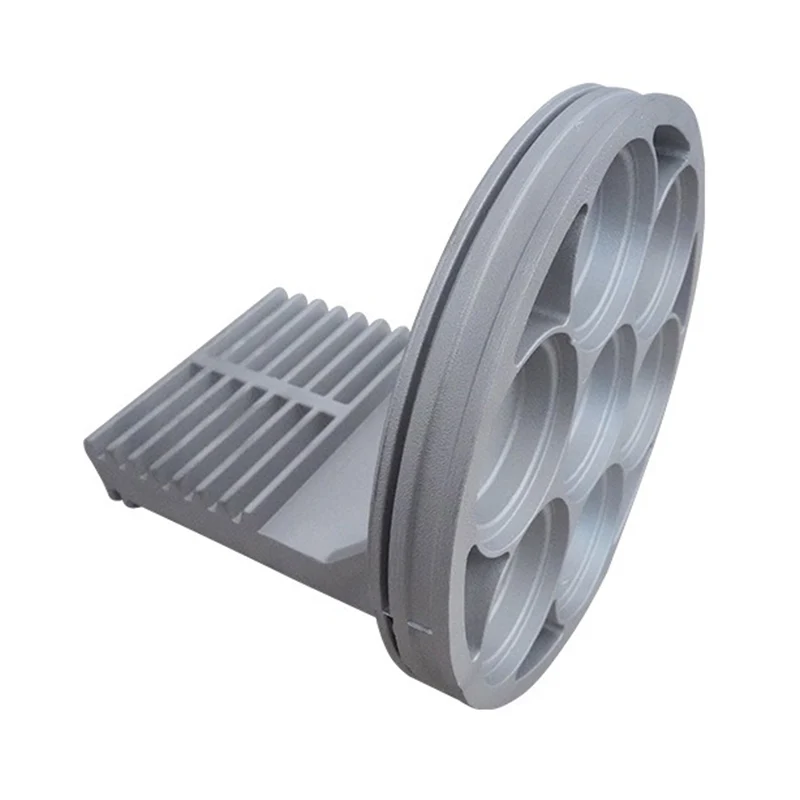

Mechanical Equipment Parts Gravity Casting Aluminum Parts

Send Inquiry

What are the advantages of Mechanical equipment parts gravity casting aluminum parts produced by Xingxin Machinery Factory for mechanical equipment parts?

First of all, with thermal conductivity, casting aluminum heat can be quickly transferred to the casting mold, casting cycle is shorter. Hydrogen and other harmful gases in the melt can be effectively controlled through treatment. Aluminum alloy casting, there is no tendency of hot brittle cracking and tearing. Good chemical stability and strong corrosion resistance. Not easy to produce surface defects, Mechanical equipment parts gravity casting aluminum parts surface has a good surface finish and gloss, and easy to surface treatment. Mechanical equipment accessories gravity casting aluminum parts of good processing performance, the production of different uses, different varieties of specifications, different properties of various castings.

Mechanical equipment parts gravity casting aluminum parts in the car is widely used, such as the engine cylinder head, intake manifold, piston, wheel hubs, steering booster shell and so on. Casting aluminum alloy has good casting performance, can be made into a complex shape of the parts; do not need a huge additional equipment; has the advantages of saving metal, reduce costs, reduce man-hours, etc., in the aerospace industry and civil industry is widely used. Mechanical equipment parts gravity casting aluminum parts can be used in the manufacture of beams, gas turbine blades, pumps, hangers, hubs, intake lips and engine magazines and so on. Also used in the manufacture of automobile cylinder heads, gearboxes and pistons, instrumentation shells and supercharger pumps and other parts.