- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

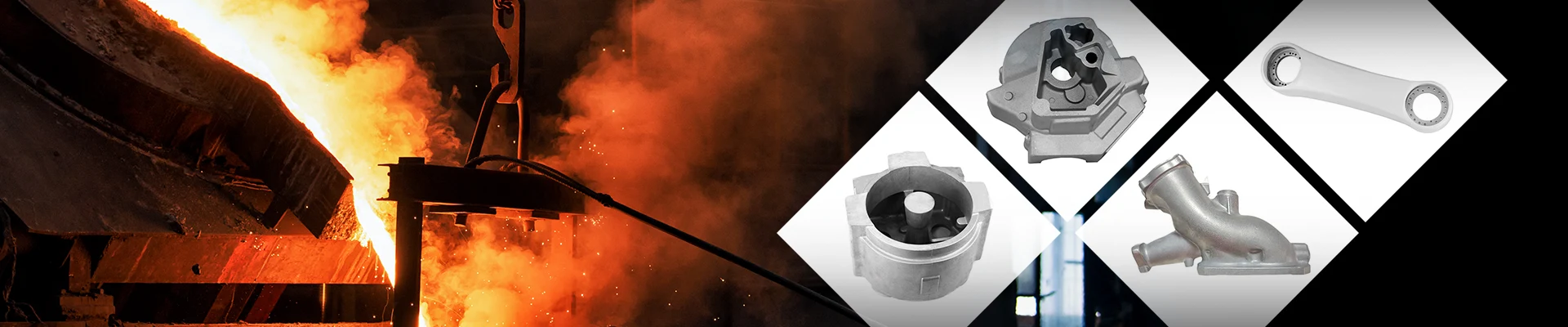

Sand Casting Aluminum Parts

Xingxin is a professional China Sand Casting Aluminum Parts manufacturer and China sand casting aluminum alloy products supplier. The principle of Xingxin Sand Casting Aluminum Parts technology is to add a sand core into the casting mold, inject the aluminum liquid into the core and then cool it down, and remove the aluminum parts from the mold after the core is completely solidified. Compared with other casting technologies, the sand casting aluminum technology is characterized by the fact that the model is generally made into two parts, and the two models need to be combined when molding.

Advantages of Xingxin sand casting technology

1. low cost: relative to other casting technology, sand casting technology is much lower cost, because the production cost of the mold is relatively low, and casting of aluminum parts of smaller size;

2. high dimensional accuracy of the workpiece: sand casting can be manufactured with high precision castings, so it is very suitable for the processing of parts with strict requirements;

3. high surface finish: the surface of Sand Casting Aluminum Parts is clean and smooth, without secondary processing;

4. high density of workpiece: the high density of aluminum parts of sand casting technology, so it has better machining performance, especially for parts with high strength requirements.

Xingxin sand casting aluminum technology in industry applications

Sand casting technology is widely used in industrial production fields, with the following application scenarios:

1. Mechanical processing industry: The Sand Casting Aluminum Parts are very suitable for the processing of parts, such as automobile parts and mechanical parts, due to the high precision and high density;

2. garden art: the aluminum parts of sand casting technology have high surface finish, so they can be used in the production of garden art, such as aluminum sculpture and fountain;

3. electronic and electrical appliances: sand casting aluminum technology can produce electronic and electrical parts, such as TV shells, computer radiators, cell phone metal shells and so on;

4. aerospace: Sand Casting Aluminum Parts has higher density and better strength, so it is suitable for manufacturing parts in aerospace field.

Xingxin sand casting aluminum process is an important metal casting process, which can produce aluminum alloy castings of various shapes and sizes through the steps of mold preparation, pouring, cooling and demolding. With the advantages of low cost, high productivity and wide range of application, this Sand Casting Aluminum Parts is widely used in automotive, aerospace, electronic equipment and other industries.

- View as

Mechanical End Cap Fittings Sand Casting Aluminum Parts

Dongguan Xingxin Machinery Hardware Fittings Co. is one of the manufacturers and suppliers of Mechanical End Cap Fittings Sand Casting Aluminum Parts in China. The company's machinery end cap fittings tumble sand casting aluminum parts are exported to more than 30 countries with its strong technical support, good quality and service.

Read MoreSend Inquiry